-

CLIENT

Gaochuan Technology -

SCALE

Medium-sized Manufacturing Enterprise -

SERVICE

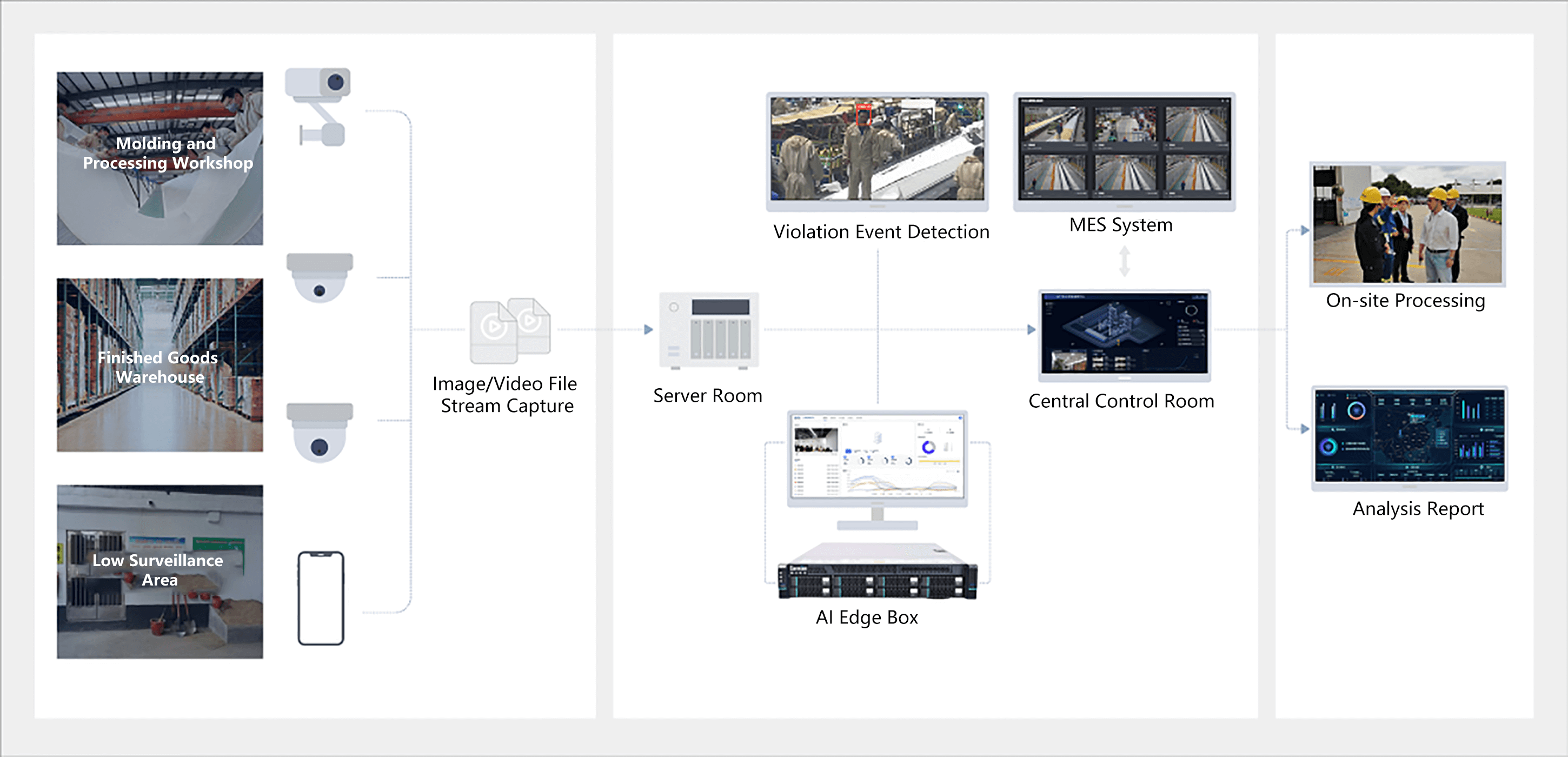

AI-based Safety Production Supervision, integrated with the MES System

Challenge :

Traditional safety management methods provide insufficient protection

Traditional factory safety management primarily relies on on-site inspections by managers and periodic video reviews to identify safety hazards. However, due to human factors, there are issues such as untimely inspections and missed checks, leading to insufficient protection of workers' safety.

Building a professional safety management team requires significant investment

Safety accidents are difficult to predict, so safety management personnel need to prevent them from the source and be constantly prepared to respond to safety incidents. However, maintaining a safety management team that is always on full alert and at peak performance represents a significant investment for many enterprises.

Solution :

Based on the standardized management indicators and data interfaces of the enterprise MES system, E-Song AI video analysis services are integrated to enable real-time approval and closed-loop processing within the MES system's online workflow, achieving seamless linkage for anomaly monitoring and handling processes.

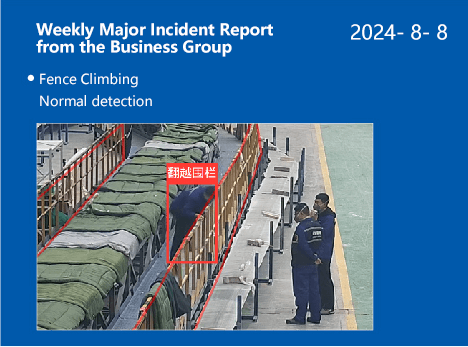

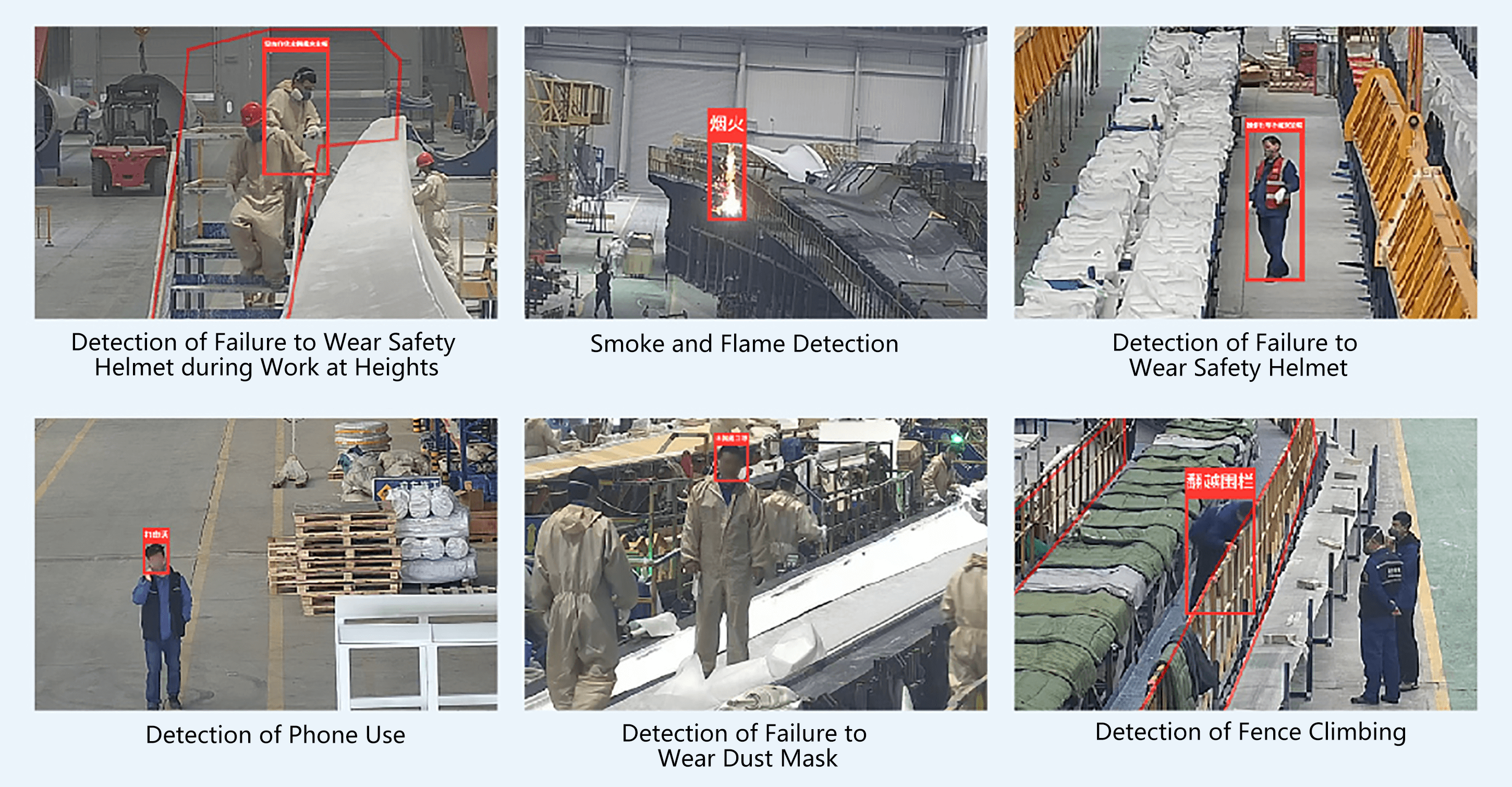

The first phase of the pilot project at the Sichuan base deployed AI algorithms, such as detection of failure to wear safety helmets, failure to wear dust masks, phone use detection, detection of climbing fences, staying under suspended loads, and smoke and fire detection, in scenarios such as the molding workshop, post-processing workshop, warehouse and logistics workshop, chemical storage, hazardous waste storage, and landfill, based on management requirements.

Measurement :

Relying on the MES system, relevant key points and rules are standardized, enabling real-time transmission of safety task information and safety management feedback, thereby establishing an end-to-end closed-loop safety management process.