-

CLIENT

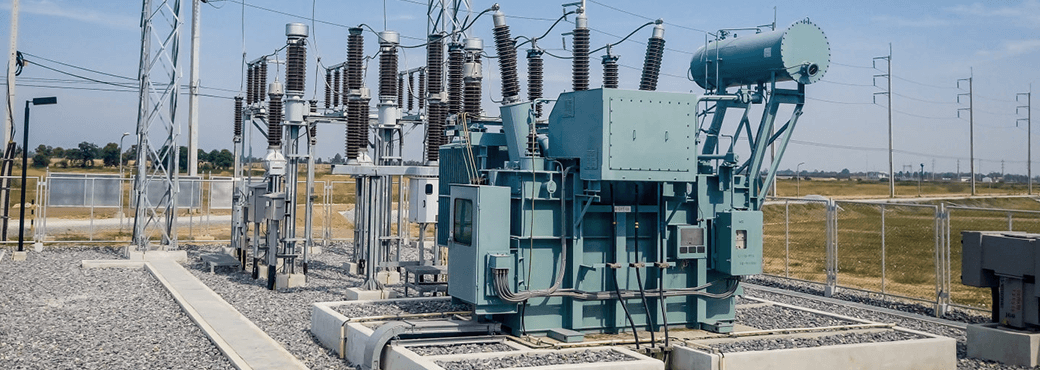

Substation Company under China Southern Power Grid -

SCALE

Municipal Substation -

SERVICE

Contributed 44% of the total ABB Group revenue in FY 2022

Challenge :

1. Difficulty in Verifying Massive Amounts of Data

Substations have installed numerous video image terminals, resulting in massive amounts of image data. If analyzed manually, it would consume a significant amount of manpower and resources, and there's a high risk of missing or misinterpreting important details.

2. Lack of Intelligent Management and Control

Traditional security systems could only provide post-event evidence collection and tracing, but they lacked the capability for intelligent and real-time analysis of video footage.

Solution :

To meet the diverse management needs of the power operation and maintenance center for substations, a modern video intelligent analysis system was deployed, tailored to the safety production requirements of substations.

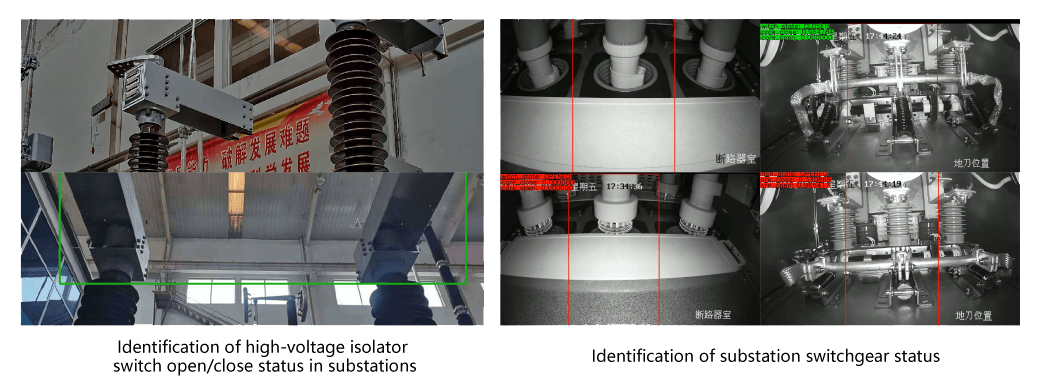

1. Intelligent Inspection of Substation Equipment

Identification of isolator switch open/close status, Identification of switchgear disconnectors, Bird nest identification, Meter identification

2. Intelligent Monitoring of Substation Operating Environment Status

Fire, smoke, indoor floor water accumulation, etc

3. Substation Safety Operations

Including line crossing/intrusion, not wearing a safety helmet, not wearing work clothes, not wearing insulated gloves, smoking, personnel falling, etc

Achievement :

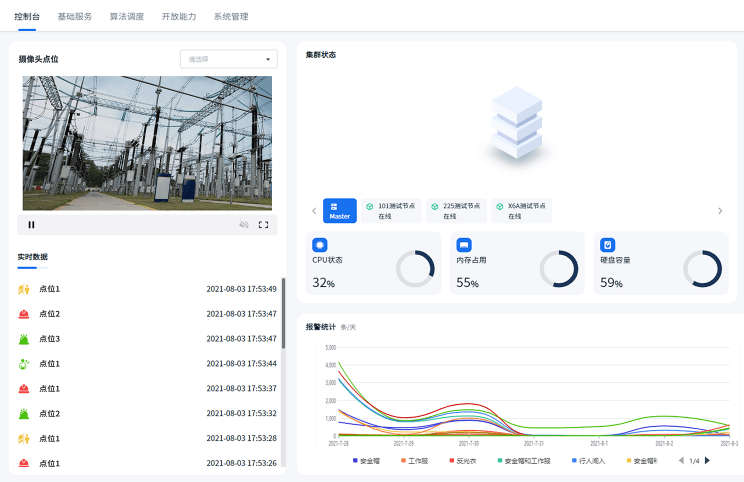

1. Data Management

The substation intelligent video analysis system integrates the management of various video points within the station, adhering to the principle of "unified access and resource sharing" in the power Internet of Things. It is capable of exchanging information with the main station system and inspection system at the city level.

2. The system has intelligent analysis capabilities

It enables personnel behavior analysis, environmental state analysis, and equipment status and defect analysis to effectively prevent and provide early warnings for safety incidents.

3. Intelligent Secondary Investigation

Timely reminders for abnormal events are provided, and 24-hour on-site problem detection is carried out in conjunction with drones and AI robots, effectively reducing the safety risks associated with manual on-site inspections.